News Center

Understanding Dual Actuator Dual Host Electric Throttle Control in Pressure Control Instruments

At its core, dual actuator dual host electric throttle control refers to a system that utilizes two actuators and two control hosts to manage throttle operations. This setup allows for increased redundancy and reliability, ensuring that pressure levels can be maintained even in the event of a failure in one of the components. The dual actuator design enables more precise control over throttle position, which is crucial for maintaining optimal pressure and performance.

One of the primary benefits of this technology is its ability to provide superior response times. The dual actuator system can adjust more rapidly to changes in demand or system conditions, leading to improved performance in applications where precise pressure control is critical. This is particularly important in industries such as manufacturing, pharmaceuticals, and aerospace, where pressure fluctuations can lead to significant operational challenges and safety concerns.

Moreover, the integration of dual host control systems allows for intelligent monitoring and management of throttle operations. Each host can independently monitor the conditions and performance of the actuators, ensuring that any anomalies are quickly detected and addressed. This capability not only enhances system reliability but also contributes to longer operational lifespans for the components involved, ultimately reducing maintenance costs.

In addition to these operational advantages, dual actuator dual host electric throttle control systems are designed with energy efficiency in mind. By optimizing throttle positions and reducing unnecessary energy consumption, these systems align with the growing emphasis on sustainability and efficiency in modern industrial practices.

It's also noteworthy that the implementation of dual actuator dual host systems can facilitate easier integration with existing infrastructure. Many modern pressure control instruments are designed with compatibility in mind, allowing for a smoother transition to this advanced technology without the need for extensive modifications to existing setups.

In conclusion, dual actuator dual host electric throttle control represents a significant advancement in the field of pressure control instruments. Its ability to enhance precision, reliability, and efficiency makes it a vital consideration for professionals seeking to improve their operational systems. As industries continue to evolve, embracing such innovative technologies will be essential in maintaining competitive advantages and ensuring optimal performance in pressure management applications.

Related News

Understanding the Importance of the Furuno 1831 Radar Plug: A Comprehensive Guide

The Furuno 1831 radar plug, especially the 24-pin square variant, is a crucial component when it comes to radar level measurement in various industries. Understanding its significance can enhance the functionality and reliability of radar systems, which are vital for applications such as shipping, oil and gas, food processing, and many other sectors where precise measurements of levels are essenti

Case Studies: Successful Implementation of 12KVA Frequency Stabilizers in Power Distribution

Case Studies: Successful Implementation of 12KVA Frequency Stabilizers in Power Distribution Table of Contents Introduction to 12KVA Frequency Stabilizers The Importance of Frequency Stabilizers in Power Systems Case Study 1: Manufacturing Sector Case Study 2: Healthcare Facilities Case Study 3: Data Centers Case Study 4: Telecommunications Industry Common Benefits of

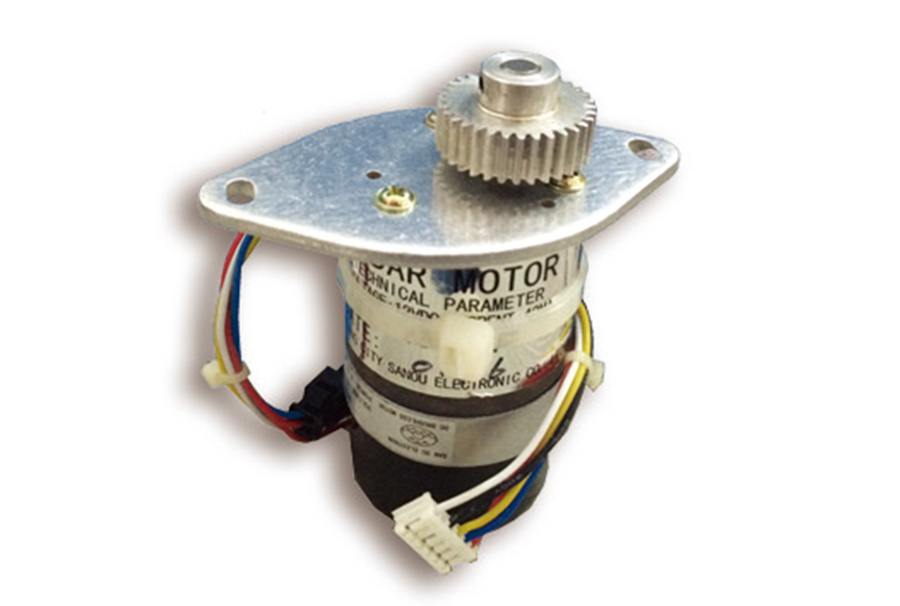

Understanding the Furuno 1832 Radar Motor: A Key Component in Marine Electronics

The Furuno 1832 radar motor is a component of Furuno's radar systems, which are widely recognized for their reliability and effectiveness in marine environments. Radar technology plays a pivotal role in ensuring safe navigation by detecting objects, such as other vessels, landmasses, and navigational hazards, which may not be visible to the naked eye, especially in adverse weather conditions. At t