News Center

Maximizing Efficiency with a Single Host Push Rod Electric Throttle Controller: Your Ultimate Guide

Maximizing Efficiency with a Single Host Push Rod Electric Throttle Controller

Table of Contents

- Introduction to Electric Throttle Controllers

- Understanding Throttle Control in Machinery

- Benefits of Single Host Push Rod Electric Throttle Controllers

- How a Single Host Push Rod Electric Throttle Controller Works

- Applications of Electric Throttle Controllers in Various Industries

- Installation and Setup of Electric Throttle Controllers

- Best Practices for Maximizing Efficiency

- Common Issues and Solutions

- Frequently Asked Questions (FAQs)

- Conclusion

Introduction to Electric Throttle Controllers

In the realm of instrumentation and control systems, the importance of optimizing operational efficiency cannot be overstated. The **Single Host Push Rod Electric Throttle Controller** is a pivotal component designed to enhance the performance of various machinery by providing precise control over throttle operations. This guide will delve into the intricacies of this technology, exploring its benefits, applications, and best practices for implementation.

Understanding Throttle Control in Machinery

Throttle control is the mechanism by which the engine's power output is regulated. It plays a critical role in managing fuel consumption, emissions, and overall system performance. Traditional throttle systems often rely on mechanical linkages, which can be cumbersome and less efficient. The transition to electric throttle controllers represents a significant advancement, enabling more accurate and responsive control over engine dynamics.

What Makes Electric Throttle Control Superior?

Electric throttle control systems eliminate the delays and inaccuracies associated with mechanical systems. **Key advantages** include:

- **Enhanced Precision:** Electric systems provide real-time feedback and adjustments, ensuring optimal engine performance.

- **Improved Responsiveness:** The instant reaction of electric systems leads to better acceleration and driving experience.

- **Reduced Emissions:** By optimizing throttle response, electric controllers contribute to lower emissions, aligning with environmental regulations.

Benefits of Single Host Push Rod Electric Throttle Controllers

The **Single Host Push Rod Electric Throttle Controller** stands out due to its unique design and operational advantages. Here’s how it helps maximize efficiency:

1. Streamlined Design and Functionality

The single host design minimizes the number of components required, reducing complexity and potential points of failure. This leads to enhanced reliability and lower maintenance costs.

2. Increased Energy Efficiency

By allowing for more precise control of throttle position, these controllers help in reducing fuel consumption significantly. Systems operate more efficiently, leading to cost savings in the long run.

3. Enhanced Control Capabilities

With advanced algorithms and sensors, the Single Host Push Rod Electric Throttle Controller can adapt to changing conditions, providing improved control during varying operational scenarios.

4. Compatibility with Advanced Technologies

These controllers can easily integrate with modern vehicle control units (ECUs) and other electronic components, facilitating the implementation of advanced features such as cruise control and traction management.

How a Single Host Push Rod Electric Throttle Controller Works

Understanding the operational mechanics of the Single Host Push Rod Electric Throttle Controller is crucial for its effective application.

Key Components

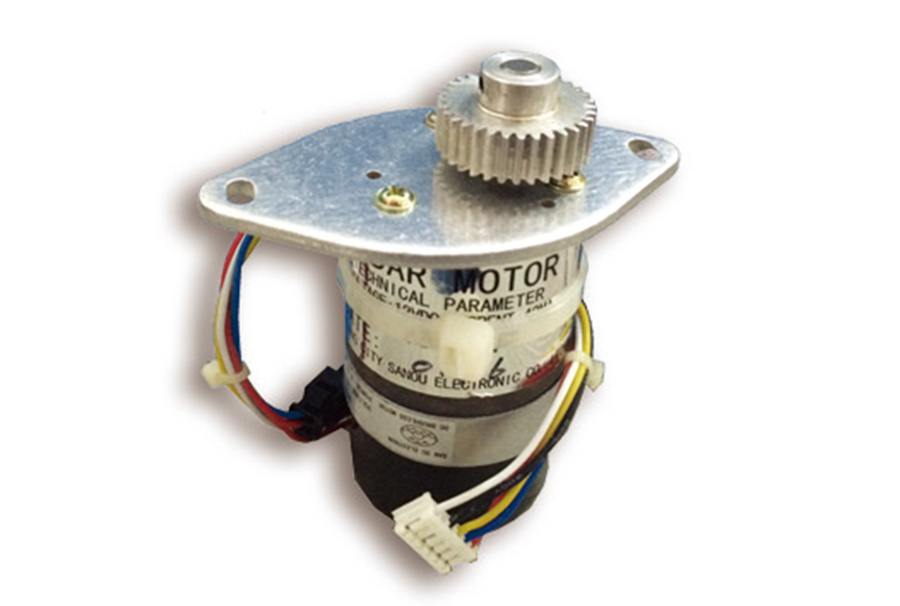

- **Electric Motor:** The core component that moves the throttle plate based on input signals.

- **Sensors:** These detect throttle position and other critical parameters, feeding data to the controller.

- **Control Unit:** This processes inputs from various sensors and sends commands to the electric motor to adjust throttle position accordingly.

Operational Overview

When the driver accelerates, the throttle position sensor sends a signal to the control unit. The control unit processes this input and commands the electric motor to adjust the throttle plate, optimizing the air-fuel mixture entering the engine. This instantaneous response leads to enhanced performance and efficiency.

Applications of Electric Throttle Controllers in Various Industries

Electric throttle controllers are versatile and find applications across multiple sectors, including:

1. Automotive Industry

In modern vehicles, they improve engine performance, fuel efficiency, and driver experience. They facilitate advanced features like adaptive cruise control.

2. Industrial Equipment

In heavy machinery, electric throttle controllers help optimize engine performance, reduce emissions, and improve overall machinery reliability.

3. Marine Applications

Used in boats and marine vessels, they provide better control of engine power, enhancing safety and performance on water.

Installation and Setup of Electric Throttle Controllers

Proper installation is paramount for ensuring that the Single Host Push Rod Electric Throttle Controller operates at peak efficiency.

Steps for Installation

1. **Preparation:** Gather necessary tools and ensure that the system is powered down.

2. **Mounting the Controller:** Securely mount the electric throttle controller to the designated location in your machinery or vehicle.

3. **Wiring Connections:** Connect the controller to the engine and sensors as per the manufacturer’s guidelines.

4. **Calibration:** After installation, calibrate the system to ensure accurate throttle response and performance.

5. **Testing:** Conduct thorough testing to verify functionality and make any necessary adjustments.

Best Practices for Maximizing Efficiency

To fully leverage the benefits of the Single Host Push Rod Electric Throttle Controller, consider these best practices:

1. Regular Maintenance

Implement a robust maintenance schedule that includes inspecting wiring, connections, and components for wear or damage.

2. Software Updates

Keep the controller’s software updated to ensure it benefits from the latest performance enhancements and bug fixes.

3. Calibration Checks

Perform regular calibration checks to ensure the system maintains optimal performance and responsiveness over time.

Common Issues and Solutions

Despite their advantages, electric throttle controllers may encounter issues. Here are some common challenges and their solutions:

1. Unresponsive Throttle

**Solution:** Check wiring connections and ensure that the control unit is receiving power. Inspect sensors for proper function.

2. Erratic Throttle Response

**Solution:** This may be due to incorrect calibration. Recalibrate the system and check for any software updates that might address performance issues.

3. Mechanical Failures

**Solution:** Ensure that components are not obstructed and are adequately lubricated. Inspect for any signs of damage that may require replacement.

Frequently Asked Questions (FAQs)

1. What is a Single Host Push Rod Electric Throttle Controller?

A Single Host Push Rod Electric Throttle Controller is an advanced device that provides precise control over engine throttle operations, enhancing performance and efficiency.

2. How does it improve fuel efficiency?

By allowing for accurate adjustments to the throttle position, it optimizes the air-fuel mixture, leading to reduced fuel consumption.

3. Can I install it myself?

While it is possible, professional installation is recommended to ensure proper setup and calibration.

4. What maintenance is required for these controllers?

Regular inspections of wiring, connections, and components, along with software updates and calibration checks, are essential for optimal performance.

5. Are there compatibility issues with older machinery?

Compatibility can vary; it’s essential to check manufacturer specifications and possibly consult with a professional.

Conclusion

The **Single Host Push Rod Electric Throttle Controller** is a game-changer in the realm of instrumentation and control systems. By optimizing throttle response, enhancing efficiency, and reducing emissions, this technology represents a significant advancement over traditional mechanical systems. Through proper installation, regular maintenance, and adherence to best practices, users can unlock the full potential of their machinery. Investing in this innovative solution is a step toward a more efficient, reliable, and environmentally friendly operational framework.

Related News

Understanding the Importance of the Furuno 1831 Radar Plug: A Comprehensive Guide

The Furuno 1831 radar plug, especially the 24-pin square variant, is a crucial component when it comes to radar level measurement in various industries. Understanding its significance can enhance the functionality and reliability of radar systems, which are vital for applications such as shipping, oil and gas, food processing, and many other sectors where precise measurements of levels are essenti

Case Studies: Successful Implementation of 12KVA Frequency Stabilizers in Power Distribution

Case Studies: Successful Implementation of 12KVA Frequency Stabilizers in Power Distribution Table of Contents Introduction to 12KVA Frequency Stabilizers The Importance of Frequency Stabilizers in Power Systems Case Study 1: Manufacturing Sector Case Study 2: Healthcare Facilities Case Study 3: Data Centers Case Study 4: Telecommunications Industry Common Benefits of

Understanding the Furuno 1832 Radar Motor: A Key Component in Marine Electronics

The Furuno 1832 radar motor is a component of Furuno's radar systems, which are widely recognized for their reliability and effectiveness in marine environments. Radar technology plays a pivotal role in ensuring safe navigation by detecting objects, such as other vessels, landmasses, and navigational hazards, which may not be visible to the naked eye, especially in adverse weather conditions. At t